Switchgear

Our free-standing self-supporting low-profile padmount switchgear can be customized to meet every switching and isolation configuration requirement for medium voltage distribution. Dead Front or Live Front padmount air-insulated and vacuum switchgear can be designed for a voltage class of 15kV – 35kV, with a current ranging from 200A – 600A and a fault closed of 40kA. An array of single-phase and three-phase styles can be fabricated for industrial, commercial, residential, or renewable energy applications.

Metal Enclosure Design

GALVANIZED CHANNEL

The metal enclosure is welded to a 3-inch galvanized channel base to reduce flexing and racking during installation.

WELDED THROUGHOUT

The metal enclosure’s galvanized channel base, roof and walls are MIG welded throughout and grounded smooth to make the metal enclosure structure sturdy and water infiltration resistant.

MEDIA BLASTED

Media blasting the metal enclosure removes metal impurities resulting in a rough surface that firmly adheres to the primer and finishing coat.

SEALANT

Once the metal enclosure has been primed, a sealant is applied to the seams to prevent water infiltration.

PRIMER & FINISH COAT

The metal enclosure is coated with 3 millimeters of epoxy primer and 3 millimeters of finishing to reduce the effect of corrosion. The epoxy coat is graffiti-resistant; use and adhesive remover to clean the defacement.

Metal Enclosure Benefits

CUSTOMIZABLE

When standardized metal enclosures do not meet your specifications due to site footprint requirements and limitations, Scott Manufacturing Solutions customizes metal enclosures to meet your specific requirements. Our 3-D modeling allows for erase in the visualization of the product, making customization seamless.

SAFE

Metal enclosures are customized to comply with IEEE, NEMA, ANSI and Western Underground Committee.

COST-EFFECTIVE

Designed to withstand the test of time. The metal enclosure 3-inch galvanized channel base, welded throughout construction and 3 millimeters of primer and finish coat contribute to the metal enclosure longevity. Resulting in a long-term, cost-effective solution that can endure harsh environments.

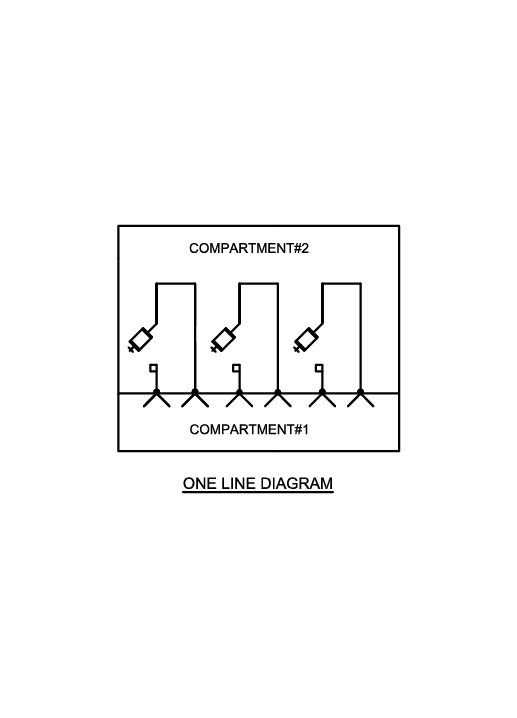

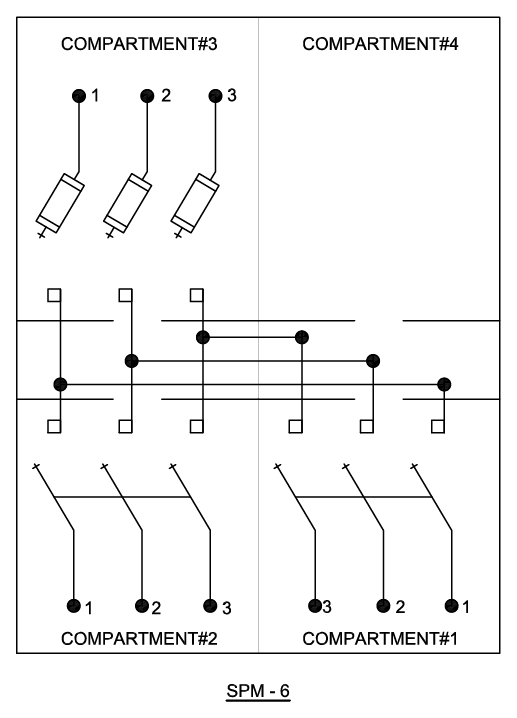

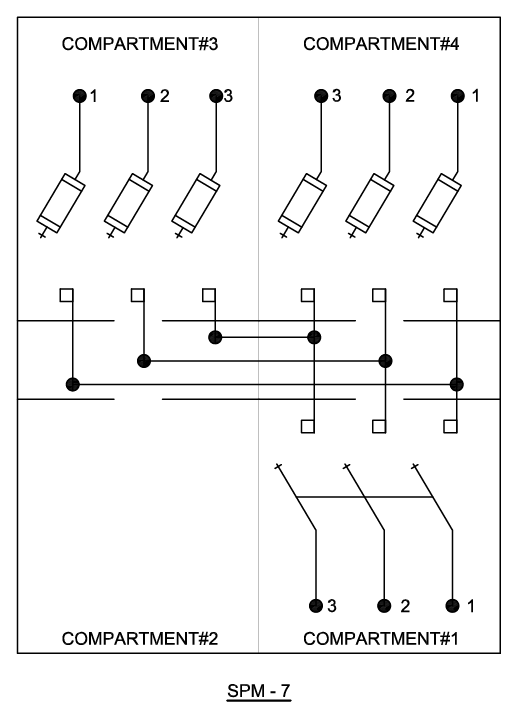

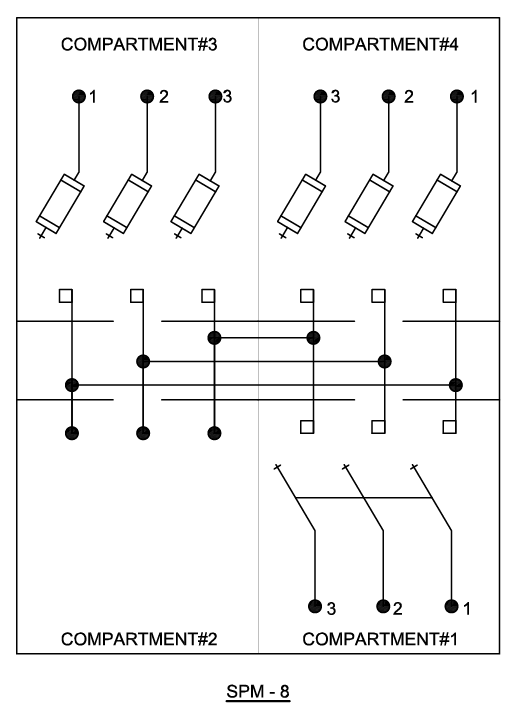

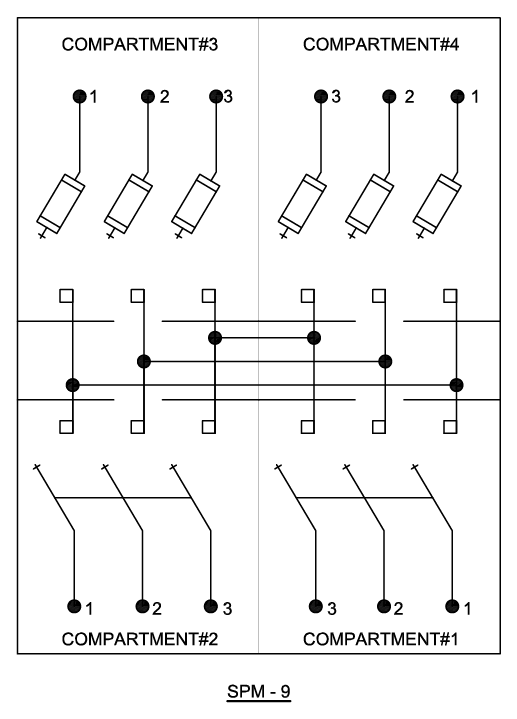

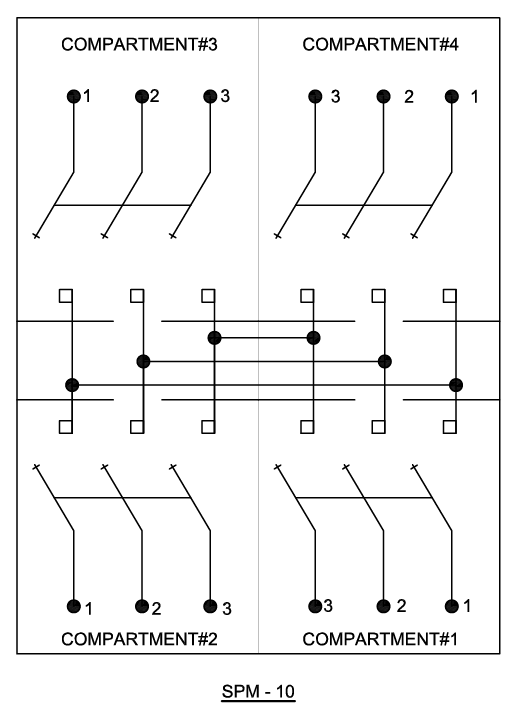

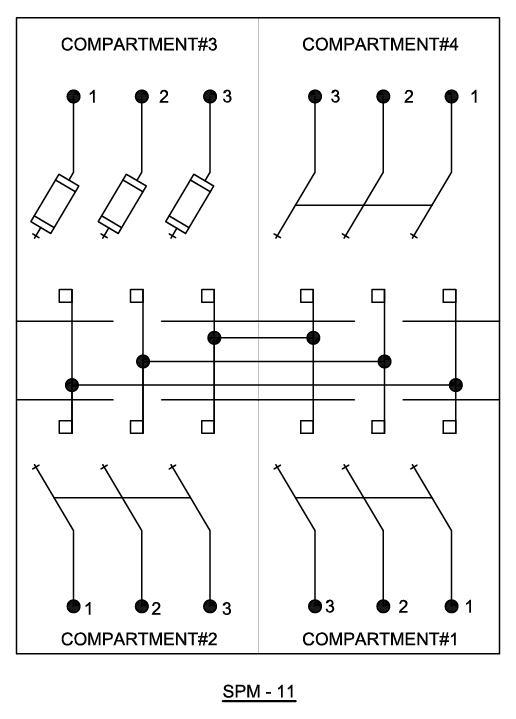

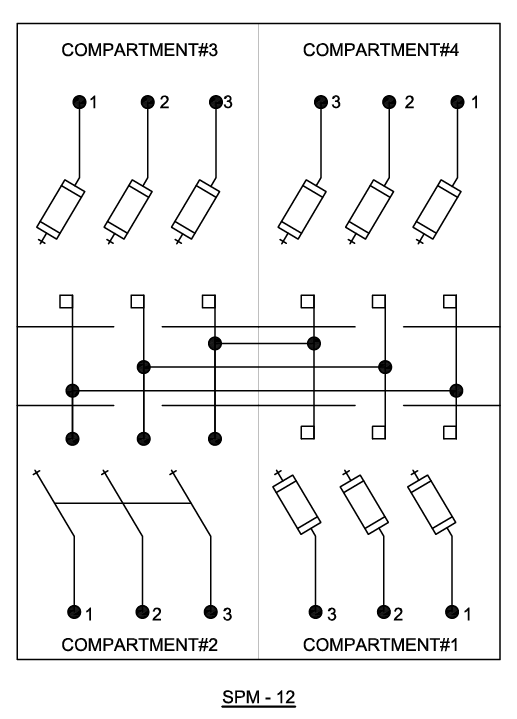

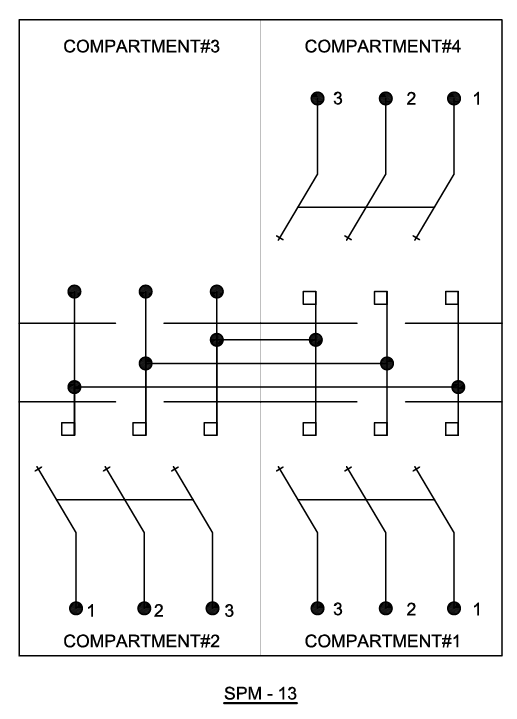

SWITCHGEAR CONFIGURATIONS

All configurations can be built in live-front and dead-front. Examples of the most popular configurations are displayed below.

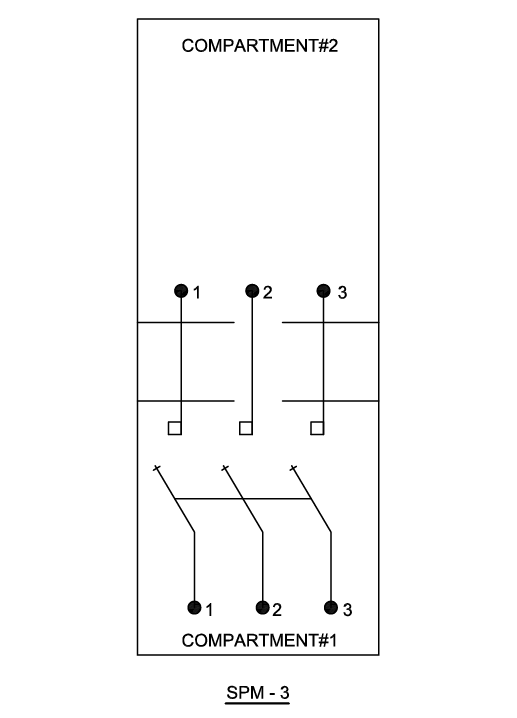

SPM – 3

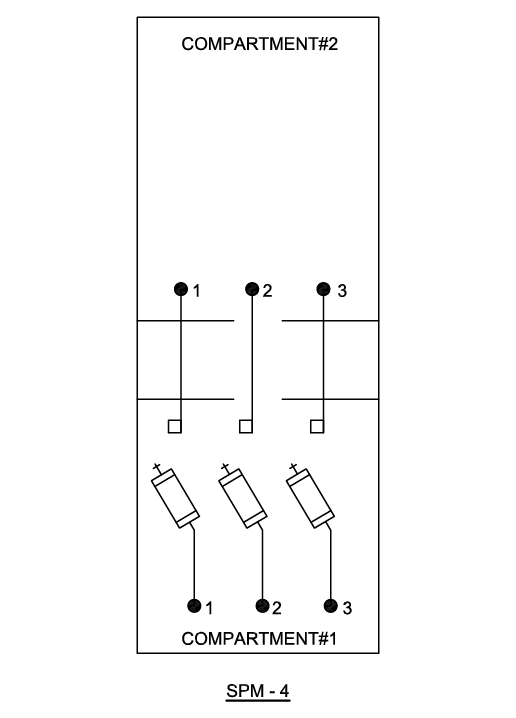

SPM – 4

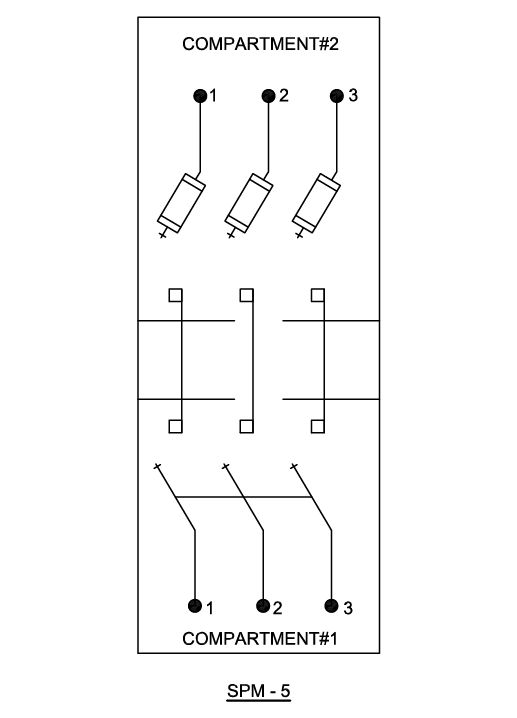

SPM – 5

SPM – 6

SPM – 7

SPM – 8

SPM – 9

SPM – 10

SPM – 11

SPM – 12

SPM – 13

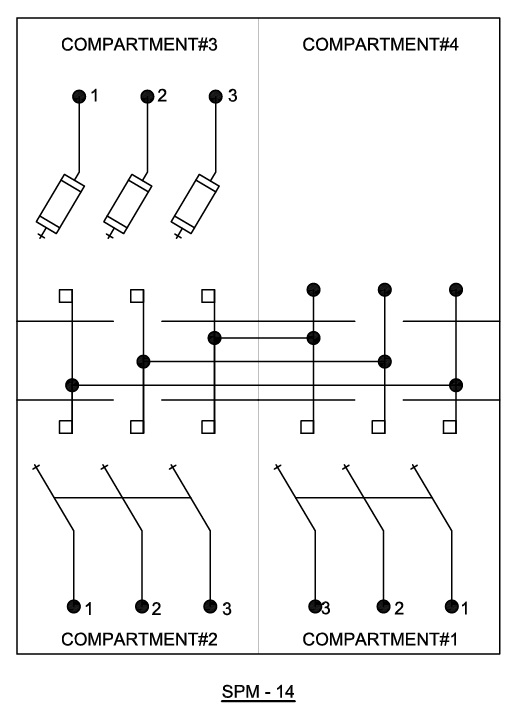

SPM – 14

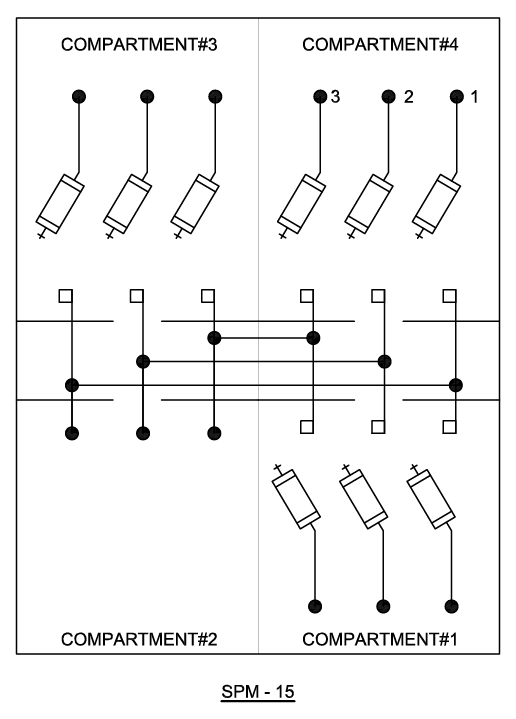

SPM – 15

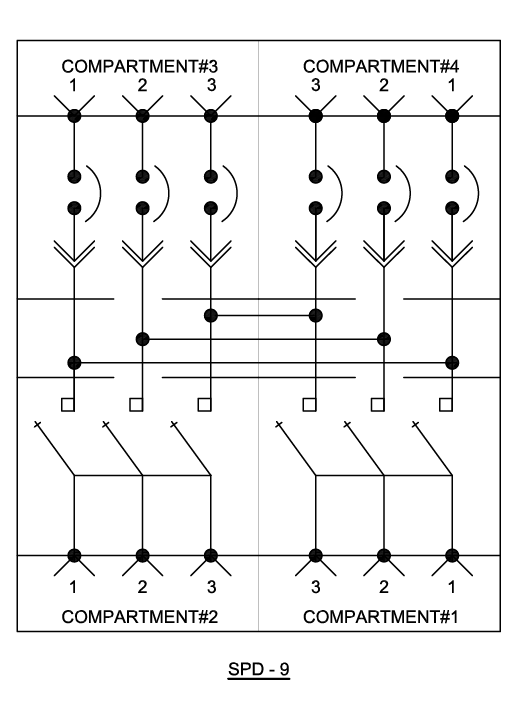

SPD – 9

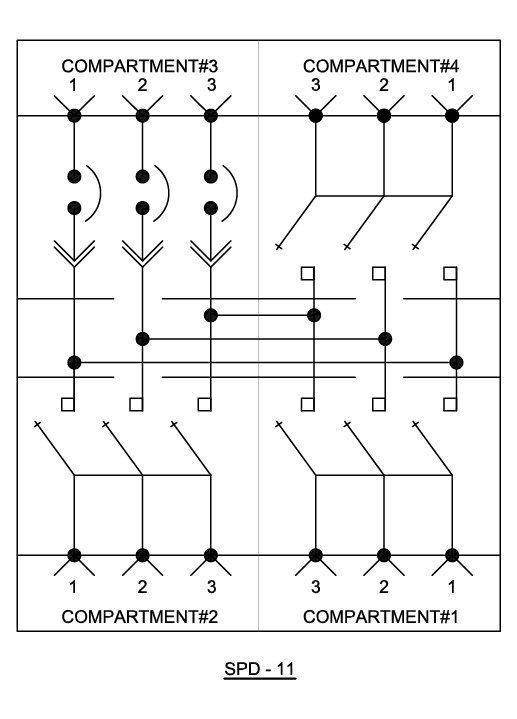

SPD – 11

Standard Features

● 12 gauge cold-rolled steel construction throughout – 13 gauge 304 or 316 stainless is available when requested

● MIG welding throughout, all welds are ground smooth

● Three-inch structural channel base is hot-dipped galvanized after fabrication

● The roof is cross kinked for both strength and drainage

● The metal enclosure is media blasted to promote adhesion of the final coatings

● The enclosure has three millimeters of universal epoxy primer and three millimeters of epoxy siloxane finish

● All seams are sealed before applying the finish coat to prevent water infiltration

● Meets ANSI C57.12.28 and Western Underground Committee 2.13 tamper resistance standards

● All door-to-metal enclosure seams are a double baffle design for extra security

● Doors provided with stainless steel pentabolt padlockable handle with vandal-resistant three-point latching

● Stainless steel door hinges

● Metal enclosure doors have lift-off capability in open position only

● Conveniently located side-mounted padlockable switch pocket

● Bold, clear cautionary labels as specified

● The circuit diagram is conveniently located inside the door

● Positive door stop locks the door in an open position

● NEMA Grade GPO-3 barriers

● Louver covers install on each vent to prevent tampering and insect infiltration

● Bare, tin, or silver plated copper bus

● Porcelain or cycloaliphatic insulators

Optional Features

● Switched and fused ways to match specified requirements

● Sensing and monitoring accessories to meet requirements

● Additional circuit configurations beyond our standard four-way

● Available as dead front or live front

● Clear hot-stick removable access barriers

● Ground sleeve riser base to match requirements

● Fuses factory installed

● Lightening arresters

● Ground bar or rod

● Ground sleeve

● Final color to match specifications

● Coastal finish with zinc-rich primer

● Hinged roof sections to allow for easier cable installation

● Factory installed leveling device

● Removable or welded lifting eyes that are 304 or 316 stainless steel